Presentation

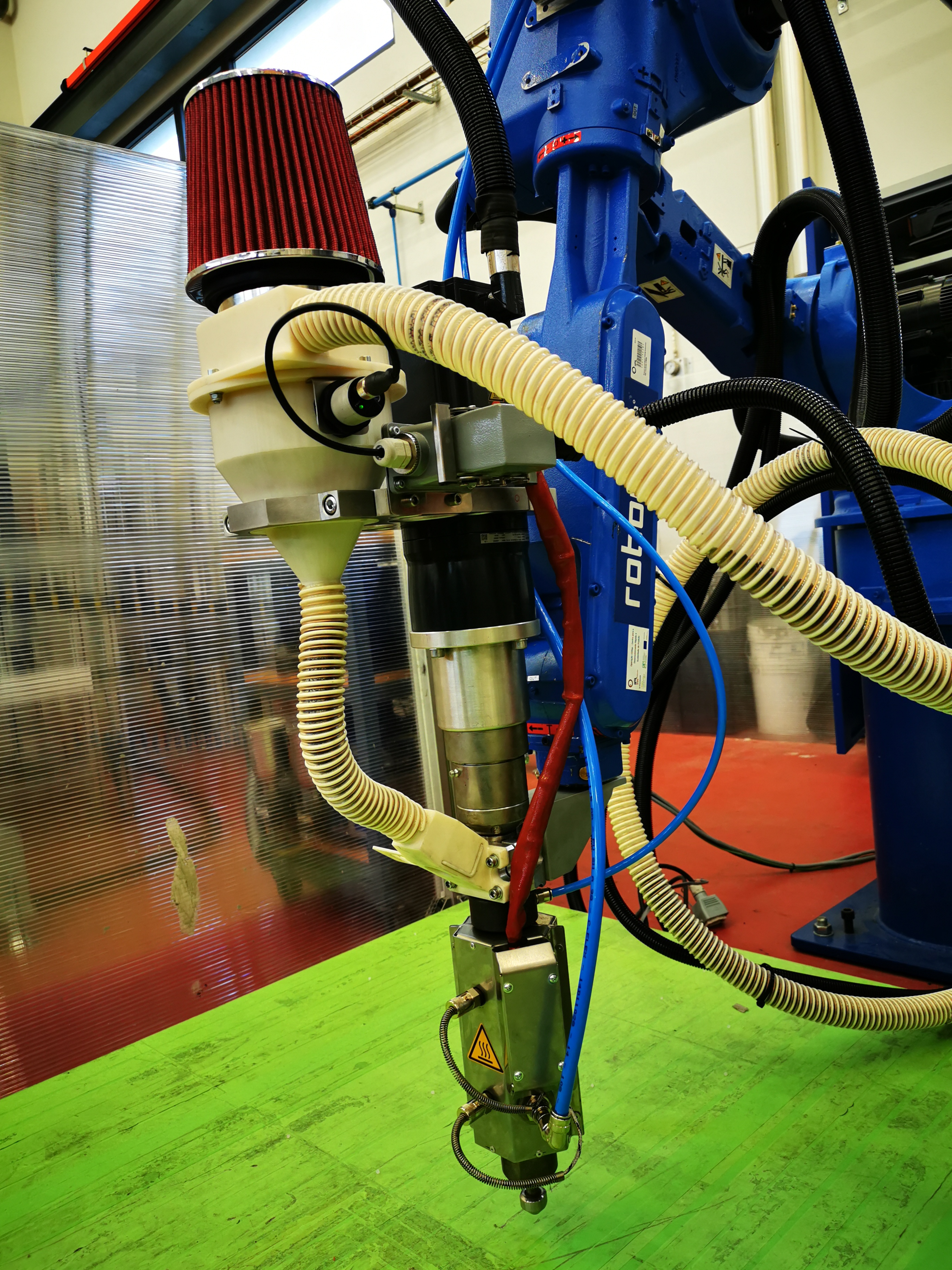

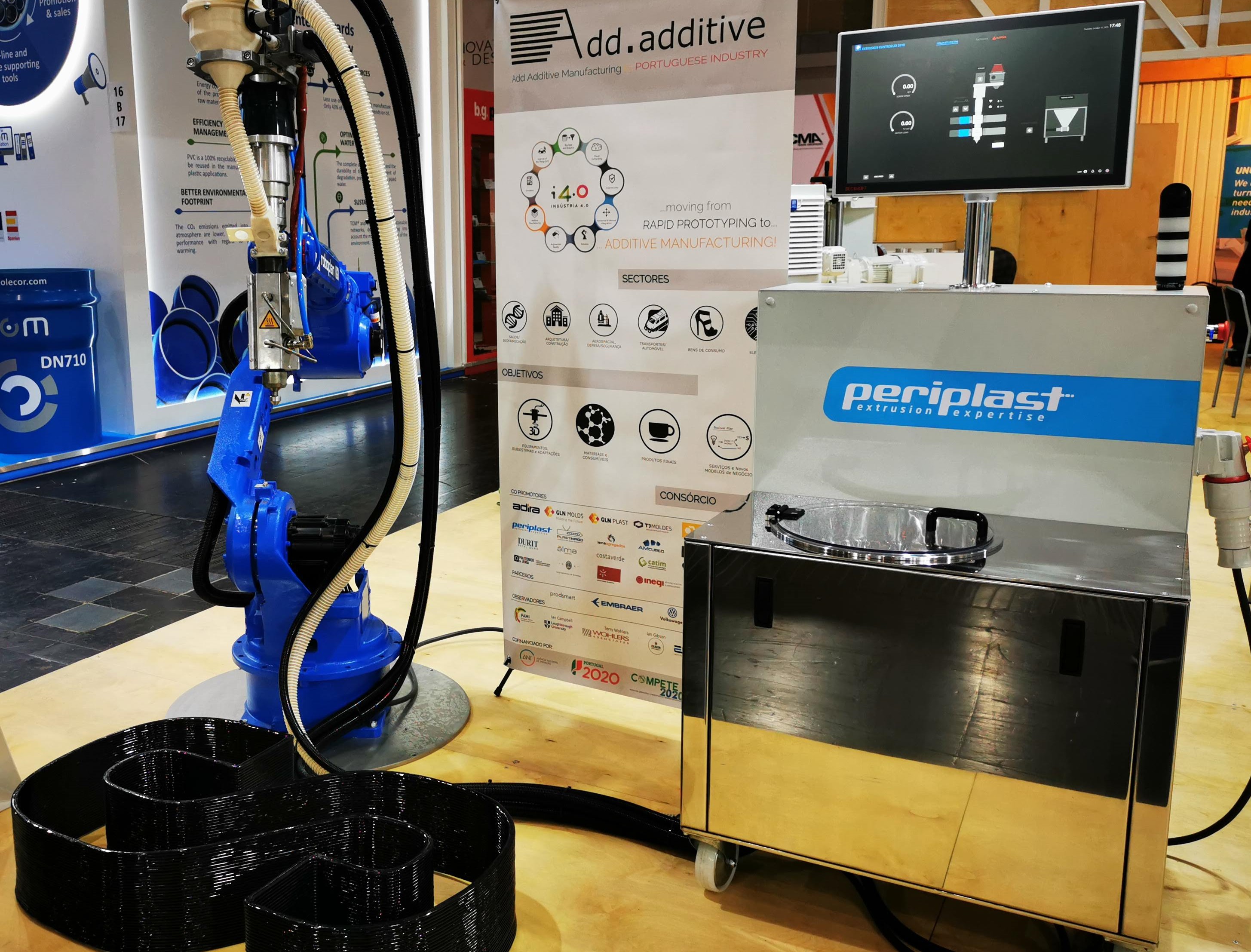

Periplast is an extruder manufacturer for more than 30 years. We are experts in manufacturing small pellets extruders like Ø20 / Ø25 / Ø30 (co-extruders). We re-engineerd these extruders and gave them a ROBOT life, creating our first 3d pellet extruder our new EXTRUBOT®:

EXTRUBOT® DESIGN PRINCIPLES:

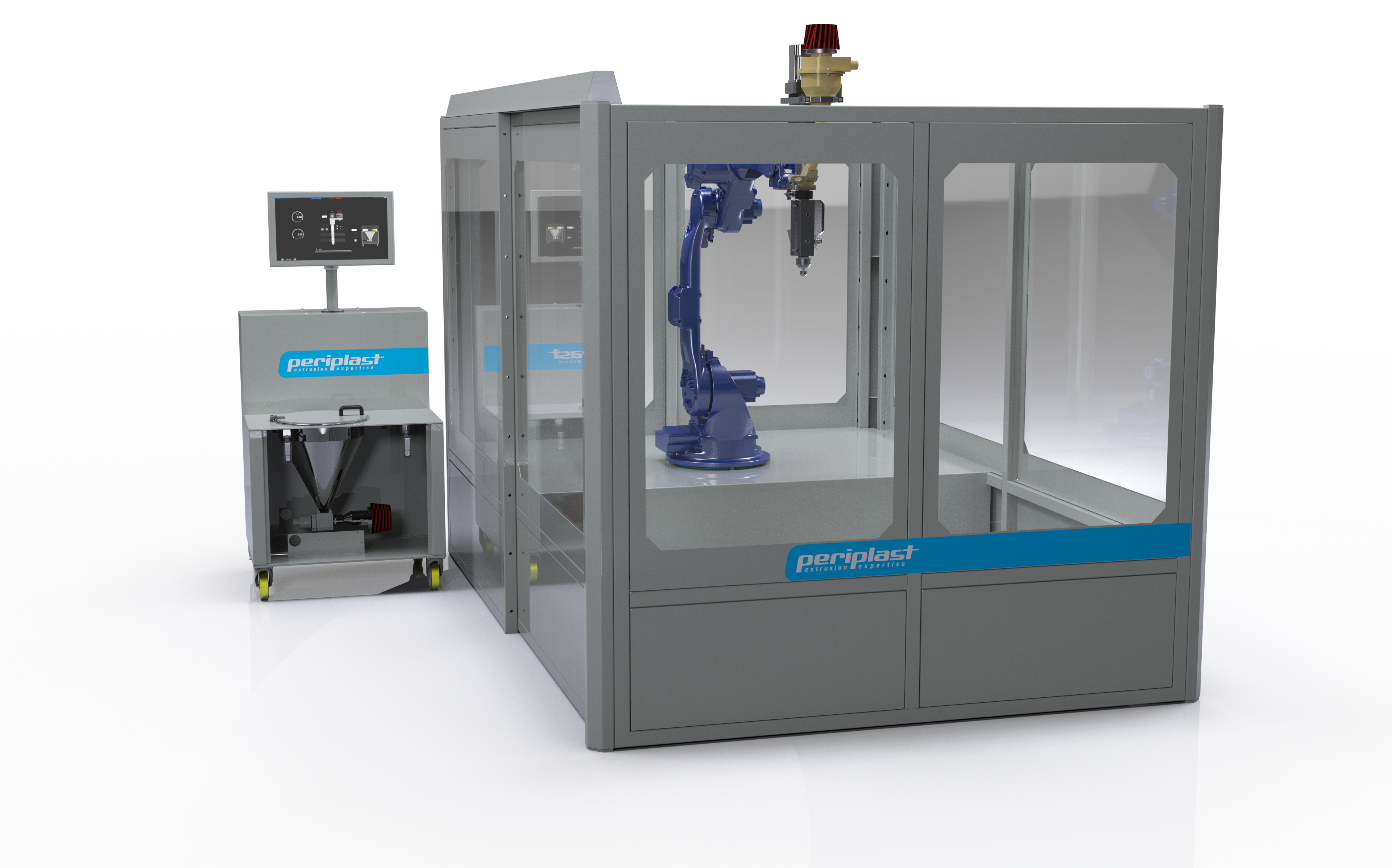

- ALL IN ONE BOX SOLUTION (EXTRUDER/ROBOT/SOFTWARE)

- Reduced Weight <25 KG, with use of light materials, and Servo Motor.

- Beautiful and user-friendly windows PC-based control software for the extruder, that can be updated with a single click.

- Plasticizing unit design prepared for high-sensitive materials with High Torque and a Max. >Temperature operation up to 400º, we can handle any polymer in the market

- No Water needed for cooling, just compressed air and electricity.

- Continuous and automatic feeding of the extruder

- Easy replace nozzel with different options and shapes (1/12mm)

- Reduces costs drastically - pelletzed materials for 3D printing is cheaper than using filaments.

- Easy and Safety

- Thermally insulated protections

- Precise Servo motor

- Heating zones to control extruder and tooling w/ thermocouples

- Recipies for different materials (Speed, Zone temperature, Heating Bed tempearature, Cooling)

- Heating Bed, for heating the print surface

- Communication with Robot (Digital/analog): 1. Start/Stop 2.Retract 3.Speed

- Material transport distance:10 meter (more on request)

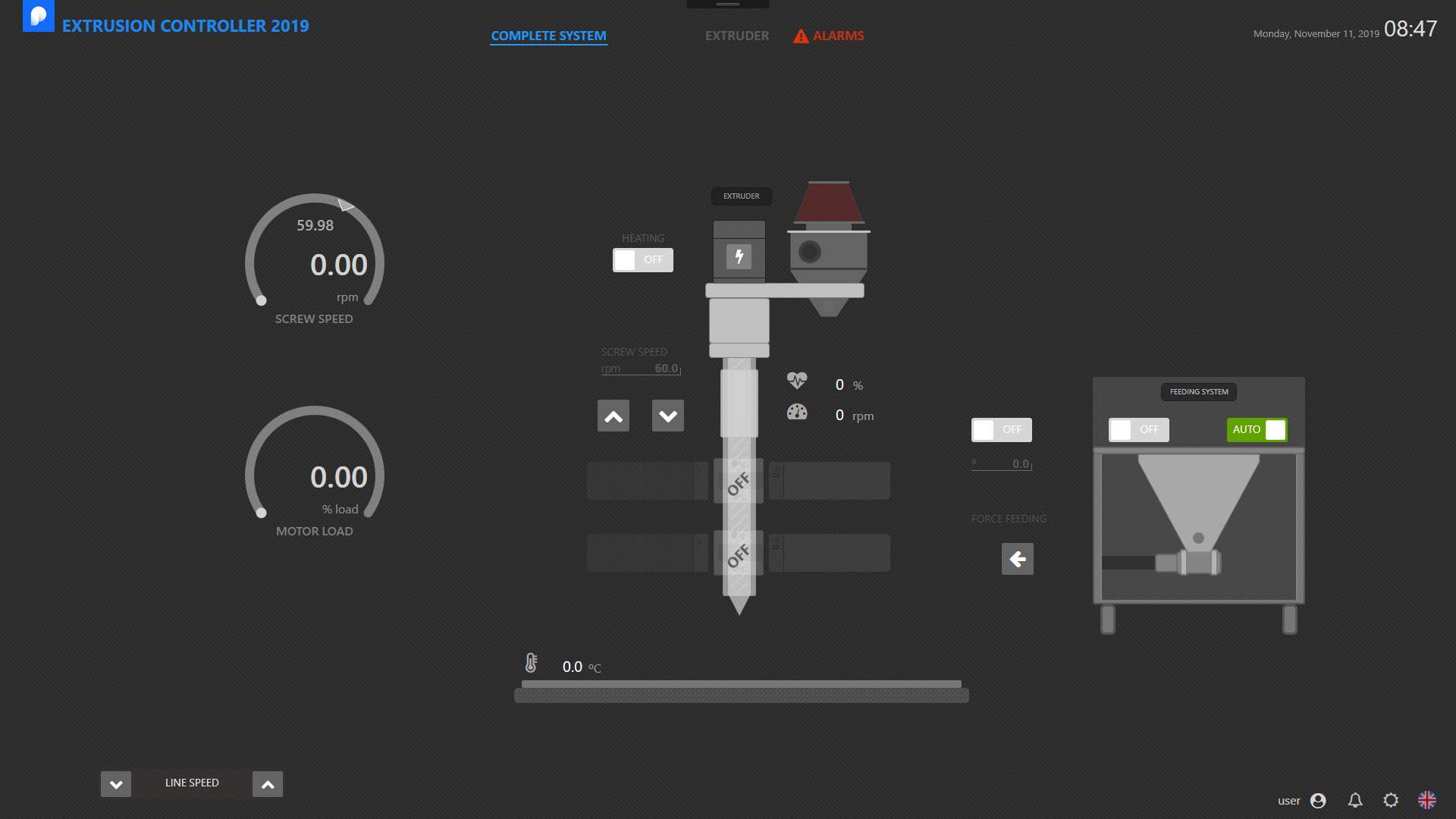

EXTRUDER SOFTWARE

PC-Base multi touch Screen (Extrusion Controller), designed for industrial extruders, which gives you full control of the EXTRUBOT®:

- Temperature Settings (Two Setpoints)

- Different recipies for each product.

- Recipies for the Heating Bed

- Communication with Robot (Digital/analog): 1. Start/Stop 2.Retract 3.Speed

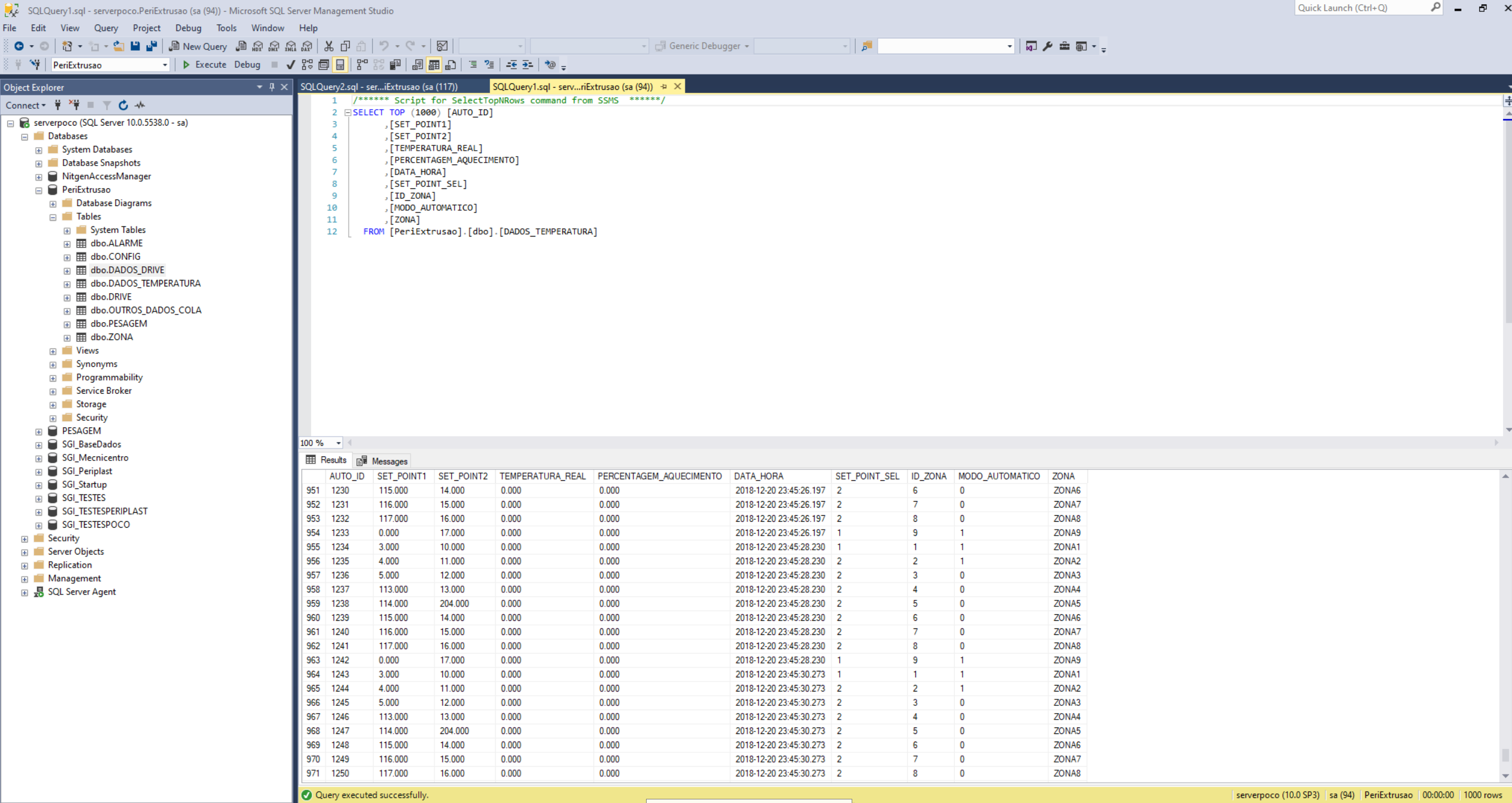

- Logging of the temperature, Drive speeds, Recepies and Operator Data

- Graphics and data record with possible SQL SERVER INTEGRATION

- Alarm log

|

|

|

|